Converting Heljan Class 23 to EM

Tom Cunnington

24th September 2016

4 minutes

The Heljan Class 23 is one of the simpler conversions to EM gauge. I don’t think there are any revolutionary ideas here, but hope this may be of use to anyone else contemplating the conversion or looking for an easy one to start with.

The model as supplied picks up electricity from the wheel on the back of the flat disc with phosphor bronze strips, and although it’s not the most robust system, with care can be used for this conversion. I used Black Beetle 12mm diameter nickel silver wheels supplied by DC Kits which are the closest solid metal wheels available, and I’ve always liked the quality despite the relative price in the UK rising recently.

I deal with one bogie at a time, and the first stage is to remove the plastic base with a small screwdriver inserted into each of the 4 small lug holes you can see in the picture above in turn to ease it off. It can be a frustrating process, as the two you have just eased out click back into place as you go for the third, but eventually it just lifts off. The inside end cross pieces (on the left in the picture) are fairly fragile, and have a habit of falling off, but they hold the bogies side frames together so need to be glued back at some stage. The drivers’ steps on the side are also fragile, and I had to glue one set back on….

With the bogie base off, the wheel sets simply lift out. They are on 2mm axles, and reusing the axle gear wheel is fairly straight forward. The wheels just pull off, so with one off I use the GW models wheel-puller to ease the gear off. I guess pliers or a vice would work as long even pressure is applied so as not to distort the gear.

Preparing the new wheel sets is a similar process – I remove one wheel (the one that is insulated) which does usually need a bit more force than the Heljan wheels. If the insulating bush comes out of the wheel, don’t worry, it all slides back later. I rough up the middle of the axle – using a couple of strokes with a course file or impressions with pliers – to ensure the gear and axle engage.

The gear is then pushed squarely onto the new axle to about the mid point. I have marked one edge of a back-to-back gauge with a centre mark to help me get the gear in the right place – easy in this case as the gears should be central. When It’s lined up, the other wheel is slid back into place using the back-to-back gauge to check it’s in place and square.

The picture here shows the two original axles on the left, one with the wheel still off. The new axles are to the right, the one on the far right has the gear on and the pin points ground off, the middle right axle is as supplied with the gear underneath.

The axles are designed for rolling stock, so the pin-points need to be removed to fit within the bogie sides. The slow way uses a file, but I tend to use Dremel with a rotary sander to gently take them down as it’s easier, and easier to avoid damaging the face of the wheel. Gently because it causes a lot of heat that could damage the axle, so just a bit at a time from each end. When the axle end is flush with the front of the wheel, I check the B2B is still right, then drop them into the bogie, taking care not to push the pickups out of place. In 3 of the 4 on this loco, the pick-ups were still fine, on the fourth I had to bend the picks out very slightly with a small screwdriver.

The bogie sides are wide enough apart not to need any modification, and the gear holds the axle centrally so I didn’t need to add packing washers. With the bogies bases clipped carefully back into place (avoiding the weak spots on the bogie), the loco worked first time on the test track. About an hour from OO to EM.

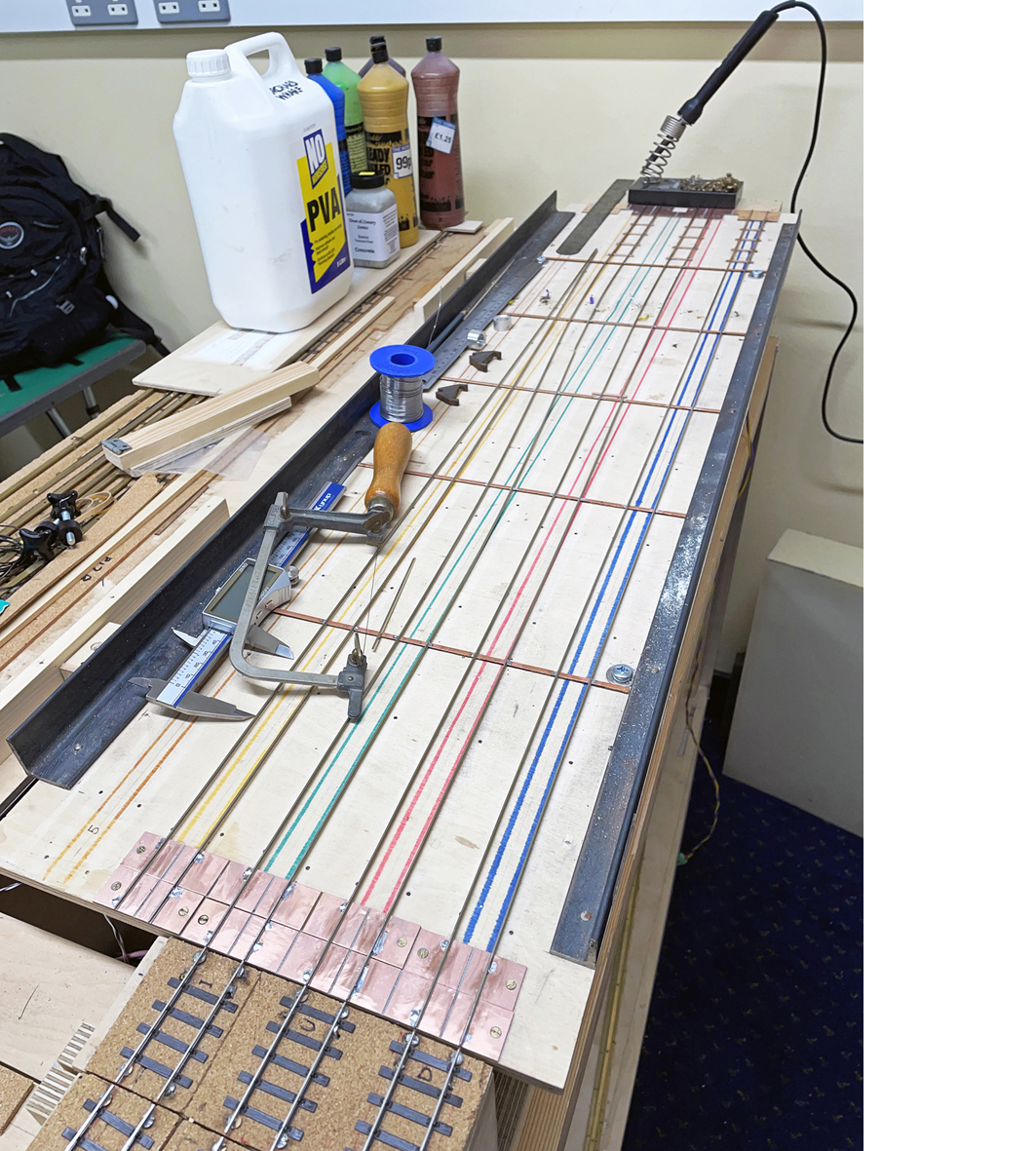

Thursday Track Nights

We are open on Thursday evenings from 7pm to 9pm at our Keen House clubrooms. Visitors are welcome, please come along and introduce yourself.

Address:

Keen House, 4 Calshot Street, London, N1 9DA

Become a member